ARGUS Umweltbiotechnologie GmbH

© 2024 ARGUS Umweltbiotechnologie GmbH

Services

Biological exhaust air treatment

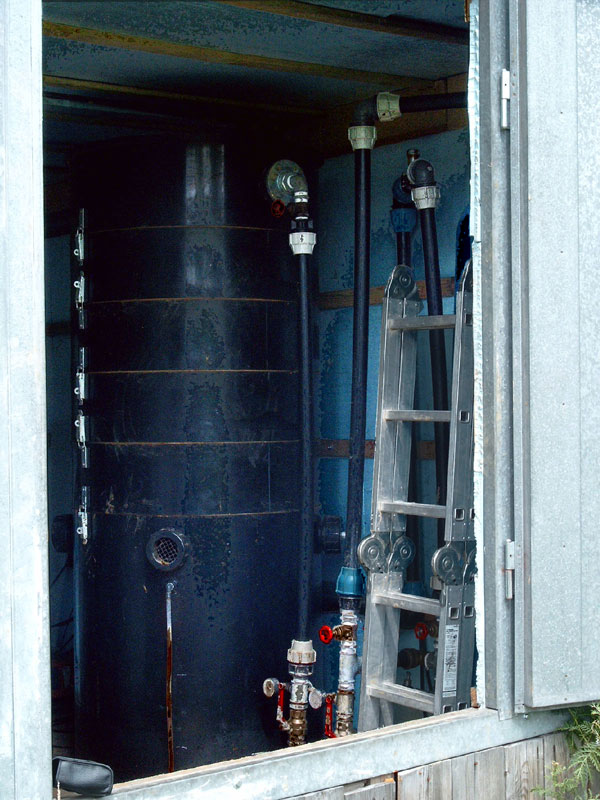

Sieve tray column enclose in

Discharge pipe with inspection opening

Sieve tray column

> 99 %

Biological Exhaust-Air Treatment

> 45 %

Air-Specific Activated-Carbon filter

> 99 %

Case Study Desorption with Biological Exhaust-Air Treatment

On the site of a former airport (Artillery range) in Brandenburg, ARGUS GmbH has been carrying out a remediation operation in the saturated zone since 2003, for the protection of drinking-water groundwater wells. BTEX-impacted groundwater is extracted from 6 wells, in parallel with pneumatic-powered oil-phase extraction. On average, groundwater is pumped from the wells at a rate of 3 m³/h with a maximum in-flow contaminant concentration of 18.000 µg/l.

In May 2010, total treated-groundwater had reached 180 000 m³. Currently, in-flow water into the treatment plant has a median concentration of approx. 1.000 µg/l.

The groundwater treatment plant consists of a sieve tray tower and an activated-carbon safety filter. The contaminated exhaust air which is produced is then directed through a biological filter and an air-specific activated- carbon filter. Remediated groundwater is then discharged directly into local receiving waters. Elevated iron concentrations (~15 mg/l) in in-flow water poses little problem for the operation of the sieve tray tower. Monthly cleaning of the sieve trays has proven to be adequate. One advantage of the sieve tray tower is the compact design which allows installation within the treatment plant container.

All required excavation works, as with pipe laying for the connection of wells to the groundwater treatment plant, were performed by ARGUS GmbH.

On the site of a former airport (Artillery range) in Brandenburg, ARGUS GmbH has been carrying out a remediation operation in the saturated zone since 2003, for the protection of drinking-water groundwater wells. BTEX-impacted groundwater is extracted from 6 wells, in parallel with pneumatic-powered oil-phase extraction. On average, groundwater is pumped from the wells at a rate of 3 m³/h with a maximum in-flow contaminant concentration of 18.000 µg/l.

In May 2010, total treated-groundwater had reached 180 000 m³. Currently, in-flow water into the treatment plant has a median concentration of approx. 1.000 µg/l.

The groundwater treatment plant consists of a sieve tray tower and an activated-carbon safety filter. The contaminated exhaust air which is produced is then directed through a biological filter and an air-specific activated- carbon filter. Remediated groundwater is then discharged directly into local receiving waters. Elevated iron concentrations (~15 mg/l) in in-flow water poses little problem for the operation of the sieve tray tower. Monthly cleaning of the sieve trays has proven to be adequate. One advantage of the sieve tray tower is the compact design which allows installation within the treatment plant container.

All required excavation works, as with pipe laying for the connection of wells to the groundwater treatment plant, were performed by ARGUS GmbH.

Remediation Performance: