ARGUS Umweltbiotechnologie GmbH

© 2024 ARGUS Umweltbiotechnologie GmbH

Services

Case Study ISCO Remediation

Alkylphenol-contamination covering a large area was found on the factory premises of a former glassworks in Berlin, which was the result of the disposal of generator-gas residues over a period of decades.

The considerably high concentrations of up to 150 000 µg/l posed a significant human exposure risk, given the elevated groundwater table (min. 1.70m below ground level) and the planned future usage of the property.

The conditions of the premises did not allow for excavation or hydraulic remediation of the site. In laboratory and field experiments the chemical oxidation of alkylphenols was achieved to a completion rate of 90% within 6 days using potassium-permanganate.

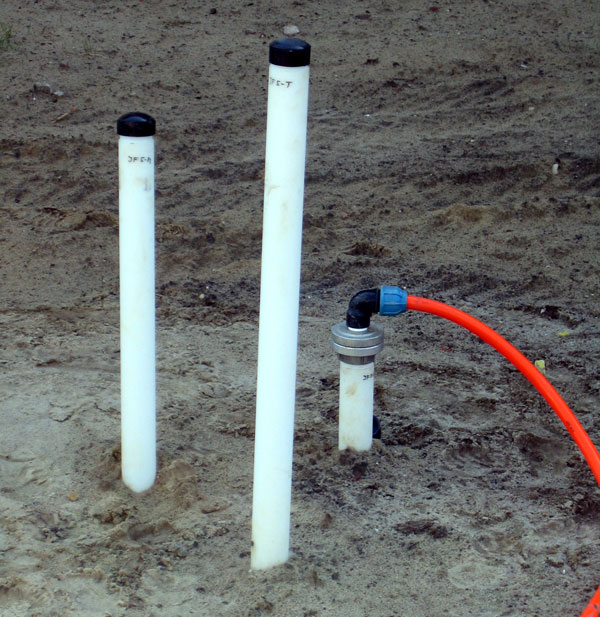

Subsequently a remediation area of approximately 600 m² was prepared for infiltration of oxidant. This consisted of a total of 153 injection-wells, installed to three specific depths, the maximum being 7m below ground level. Within one year, 4 injection-cycles and a total of 5600 kg potassium-permanganate were infiltrated.

Excluding a small portion of the targeted remediation area, alkylphenol concentrations sunk over this period to < 3000 µg/l. This accounts for a reduction of 98%. For stimulation of biodegradation of the remaining contamination, the addition of indigenous microorganisms, in the form of a slurry, was subsequently carried out through the groundwater injection-wells. Available oxygen was also temporarily altered to assist microbiological development.

Due to the public accessibility of the property, the infiltration events were exclusively carried out using mobile mixing/dosing equipment, which was able to be erected during the working week.

The considerably high concentrations of up to 150 000 µg/l posed a significant human exposure risk, given the elevated groundwater table (min. 1.70m below ground level) and the planned future usage of the property.

The conditions of the premises did not allow for excavation or hydraulic remediation of the site. In laboratory and field experiments the chemical oxidation of alkylphenols was achieved to a completion rate of 90% within 6 days using potassium-permanganate.

Subsequently a remediation area of approximately 600 m² was prepared for infiltration of oxidant. This consisted of a total of 153 injection-wells, installed to three specific depths, the maximum being 7m below ground level. Within one year, 4 injection-cycles and a total of 5600 kg potassium-permanganate were infiltrated.

Excluding a small portion of the targeted remediation area, alkylphenol concentrations sunk over this period to < 3000 µg/l. This accounts for a reduction of 98%. For stimulation of biodegradation of the remaining contamination, the addition of indigenous microorganisms, in the form of a slurry, was subsequently carried out through the groundwater injection-wells. Available oxygen was also temporarily altered to assist microbiological development.

Due to the public accessibility of the property, the infiltration events were exclusively carried out using mobile mixing/dosing equipment, which was able to be erected during the working week.

Injection wells

Injection wells

filter sections in different depth ranges

filter sections in different depth ranges